- Contact Person : Ms. Qiu Jenny

- Company Name : Zibo Guanjia Trading Co., Ltd.

- Tel : 86-533-6076009

- Fax : 86-533-6076009

- Address : Shandong,Zibo,A1525, NO. 200 Huaguang Road, Zhangdian District

- Country/Region : China

- Zip : 255000

fireproof insulation (NBR+PVC foam insulation maufacturer)

NBR Rubber foam fireproof insulation material

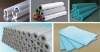

Rubber foam is a flexible and lightweight elastomeric material designed primarily for thermal insulation. Our product comes in black or other colors, & is available either in tubing or sheet form. The extruded flexible tubing is specially designed to fit the standard diameters of steel & copper pipings. Sheets are available in pre-cut size, or in rolls. Several items of ancillary products are also available like adhesive glue water, adhesive tapes, etc.

Features

Thermal insulation materials are used primarily to insulate another material (or surface) to prevent or significantly reduce the thermal energy (heat) flow to preserve either hot or cold temperatures within the insulated material thus enabling energy and cost savings.In addition, as thermal insulation is provided by covering the materials or surfaces required to be insulated with the thermal insulation materials chosen, depending on the type of insulation materials used and its application purpose, thermal insulation materials are also used to provide other secondary insulation purposes such as the following:-

to prevent condensation or frost formation on cooling systems and chilled water and refrigeration lines and thermal bridging;

acoustic, noise and vibration insulation;

shock absorption or as a cushioning material against physical or mechanical impact;

to conserve energy and costs and as a safety precautionary measure against unwanted accidents or damage;

protects items insulated from other environmental hazards such as salt water, sunlight or sunrays (ultra violet ("UV") attacks), oil and chemicals, dusts, settlement and growth of viruses, bacteria, moulds and fungi;

to withstand extremely high or low temperatures;

to provide fire resistance and a low smoke and toxic emissions in the event of fire;

to provide an aesthetic finishing look and to provide insulation without allergy or other harmful medical effects especially if used outdoors and subject to public viewing and contact; and

protects pipes from corrosion in the oil and gas and petrochemical industry.

rubber foam insulation analysis

1, Have very low water absorption or water vapour permeability

2, Environmental friendly - No trace of CFC or HCFC

3, Corrosion resistant - Very low water penetration or materials shrinkage, hence corrosion free

4, Fire resistant

5, A form of synthetic rubber or artificially-made polymer material

6, Synthetic rubber serves as a substitute for natural rubber

7, Closed-cell

8, Low water absorption and water vapour permeability

9, Natural skin outside to prevent water vapour penetration

10, Tough external: resistant to tears

11, Good oil and chemical resistance

Preformed Flexible Elastomeric Cellular Thermal Insulation Technical Feature Standard: GB/T 17794-2008 | |||

Item | Unit | Performance | |

Apparent Density | Kg/m³ b/ft³ g/cm³ | 40~80Kg/m³ 2.5~5.0b/ft³ 0.04~0.08g/cm³ | |

Working Temperature | °C °F | -50~110°C -58~230°F | |

Combustibility | Ⅰ Oxygen index≥32 Ⅱ Oxygen index≥26 | ||

Heat Conductivity | -20°C(mean temperature) 0 Celsius degree (mean temperature) 40°C(mean temperature) | W/(m·k) | ≤0.034 ≤0.036 ≤0.041 |

Vapor Performance | Coefficient µ Factor | - | ≤1.3×10-10 ≥1.5×103 |

Vacuum Water Absorption | % | ≤10 | |

SDR | % | ≤75 | |

Dimension Stability (105°C±3°C,7d) | % | ≤10 | |

Tearing Strength | N/cm | ≥2.5 | |

Compression spring back rate (compression rate: 50% Compressing time: 72h) | % | ≥70 | |

Ozone Resistance | - | No Crack | |

Anti-aging Property | - | Slight crinkle, no crack, no pinhole, no distortion. | |

Sheet Size | Standard thickness: 6/10/13/15/20/25/32mm or 1/8", 3/8", 1/2", 5/8", 3/4", 1", 1-1/4", (other thickness may be available on request ); Roll Width: 1m/1.2m/1.5m Length: 10m, 8m or according to order | ||

Tube Size | Standard wall thickness: Standard thickness: 9/13/15/20/25/32mm or on request; Standard length: 1.83m/2m; (6'/6.6') ID (inner diameter): 10-13-16-19-22-25-28-32-35-38-42-45-48-54-57-60-67-76-89-108mm (3/8", 1/2", 5/8", 3/4", 7/8", 1", 1-1/8", 1-1/4", 1-3/8", 1-1/2", 1-5/8", 1-3/4", 1-7/8", 2-1/8", 2-1/4", 2-3/8", 2-5/8", 3", 3-1/2", 4-1/4") | ||

The flexible, foamed rubber tubes and sheets are used to insulate pipes and ductwork in buildings, but they also come into their own in demanding industrial applications. The products prevent condensation forming, absorb sound and vibrations and protect installations against energy losses. This is a growth market as, in view of the rapid pace of climate change and rising energy prices, the insulation of building equipment and industrial installations will play an even more important role in the future. The requirements made in the national rules and regulations on energy saving in buildings are being tightened and at the same time measures to increase energy efficiency are becoming increasingly important for economic reasons. Nowadays, when buildings are refurbished to improve their energy efficiency, the insulation of installations is considered to be one of the most effective and cost-efficient single measures.

Feel free to call me to talk details by phone: +0086-187 6439 2637.

fireproof insulation (NBR+PVC foam insulation maufacturer)